Services

Injection Grouting

Grout is a dense fluid which is used to fill gaps or used as reinforcement in existing structures. Grout is generally a mixture of water, cement, and sand, and is employed in pressure grouting,

embedding rebar in masonry walls, connecting sections of pre-cast concrete, filling voids, and sealing joints such as those between tiles. Some common uses for grout in the household include: filling in tiles of shower floors and kitchen tiles. It is often color tinted when it has to be kept visible, and sometimes includes fine gravel when being used to fill large spaces (such as the cores of concrete blocks). Unlike other structural pastes such as plaster or joint compound, correctly mixed and applied grout forms a waterproof seal.

Although both grout and its close relative mortar are applied as a thick emulsion and harden over time, grout is distinguished by its low viscosity and lack of lime (added to mortar for pliability); grout is thin so it flows readily into gaps, while mortar is thick enough to support not only its own weight, but also that of masonry placed above it

Injection methods

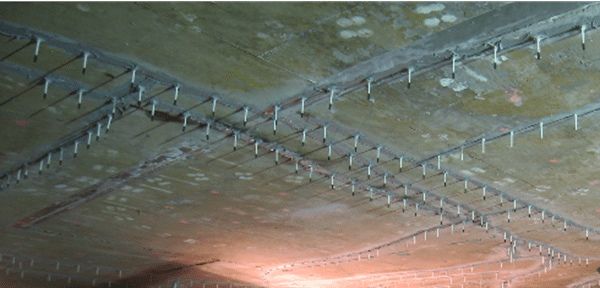

Typically, grouting is carried out is by driving pipes or boring holes into the ground, and then pumping the grout solution at high pressure through inserted tubes.

The extent of grouting required for a particular area is determined through investigation of ground conditions and the calculation of a drilling pattern. This considers the size, spacing and depth of the holes required. The type of grout and the particular ground conditions will influence the spacing of the holes.

Site conditions will influence the tools used for the boring process, but pneumatic tools, diamond drills or wash-boring are the most common. Alluvial soils are prone to collapse and so holes are usually cased.

The pressure of the grout injection is dependent on soil conditions, and in-situ testing may be carried out before the correct pressure is determined. Pressures usually range from 1 N/mm2 for sands to 7 N/mm2 for rock.

The Advantages of Epoxy Grout

While epoxy grout price is pretty stable in the higher end of the market, the marginal extra cost will be well worth your time. Not only will your tiles look better, but they will feel better too. Why? Check out this list of benefits and get ready to convert to the epoxy debate.

Easy to Clean: Cleaning grout is a time-sucker for many home owners. Even if the tiles you’re installing aren’t your own, think about how you feel about your own cleaning duties back at the homestead. Cement grout attracts dirt, grime and grease, making it near impossible and time consuming to get it clean without considerable effort. Epoxy is a breeze to keep spick and span, it doesn’t absorb stains, slurp up greases or hold onto dirt – a simple alkaline grout cleaner dissolves the refuse and that’s the end of it.

Flexible: Epoxy isn’t rigid or gritty like regular grout. In fact, when throwing around the epoxy grout vs regular grout discussion, epoxy is always noted for its elasticity and durability. It does not wither with time, considered utterly shrink-proof and bendy, moving with the building as weather influences the foundations and walls. Commercial business owners fully embrace the powers of epoxy grout – imagine the nightmare of cleaning up an industrial kitchen after you’re warm and relaxed at home? Chefs swear by epoxy.

Low Absorbency: Epoxy grouts are highly water resistant. Instead of suffering the same water ingress as cement and sand based grouts, the water simply sits on top, waiting to be cleared away or dried by the sun. Outdoor areas are regularly epoxied, along with kitchens and bathrooms – specialist products like Megasealed’s Megagrout MG11 is environmentally friendly, chemically gentle and 100% effective.